|

A circle of the desired size is marked on the material chosen, in this case Nylon 6-6.

Mounted to a fixture with double-sided tape, the mounting hole is bored.

Back to the top gempage.

NEW!! Casting the 95%tin/5% Antimony Laps!

|

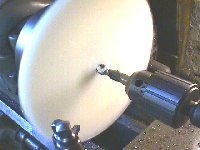

The outside diameter is turned, and if needed, the face machined flat.

Bimetal or inlaid laps:

By machining a recess into a bronze or iron lap, a bimetal lap can be made. Simply fill the recess with solder, tin, 95/5 tin/antimony, pewter, etc., and then machine the surface flat. The outer band of the base metal gives fast cutting action, while the tin center provides a smooth prepolish.

|