Gearloose Lapidary Products:APPLICATIONS

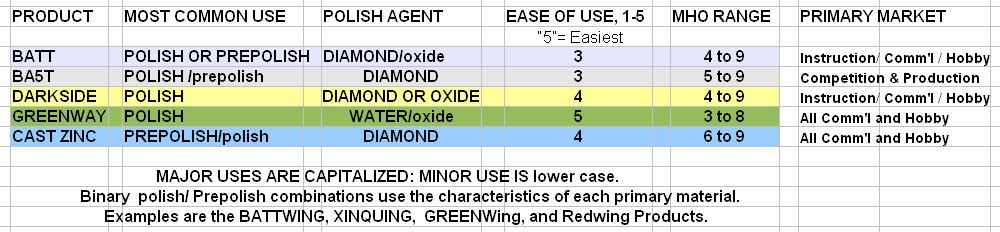

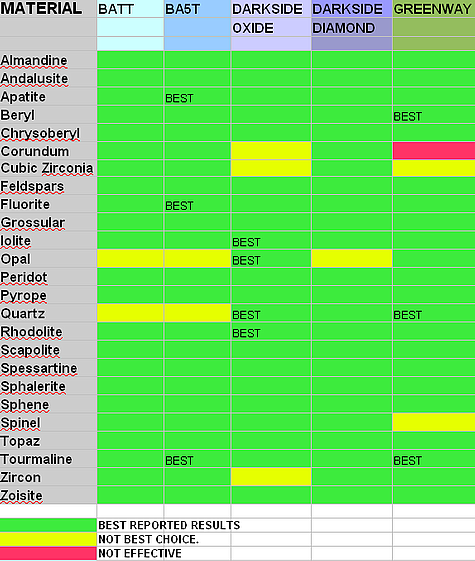

These tables are suggestions for use of the various Gearloose lap products.They are based on experience reports from a wide variety of faceters, from beginners to competition and production cutters, and reported on the Faceters' forums online over the years. All individuals use differing techniques, with variations in lap speed, pressure, wetness, and sweeping rate, so these tables are suggested starting points. The briefest summary is this: Following cutting on a #600 lap: PREPOLISH: 3000 Diamond on BATT™ *OR* 8000 Diamond on Cast Zinc POLISH: QUARTZ: CeO or Chrome Oxide on DARKSIDE™ OR GREENWAY™ Everything from fluorite to sapphire: BATT™ 60K or 100K Diamond In addition, Beryls/Garnets are especially responsive to Chrome Oxide/Darkside™ Peridot and tourmalines are polished exceptionally well with Alumina on Darkside, but have traditionally been done on BATT™ with diamond.

BACK to Index |