Machining Copper, without oil smoke or pain.

I had to machine a recess in an 8" copper disk for a part I manufacture.

The copper I use is "ETP" copper, or "Electrolytic Tough Pitch".

The first time I tried it, it took many hours, using

carbide inserts. I had to use oil, and it was a disagreeable job. Traces of the cutting oil interfered

with bonding later in manufacture.

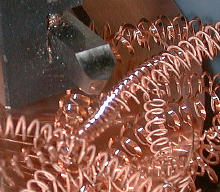

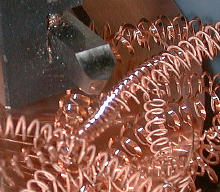

But a properly ground and polished tool actually makes turning this

material FUN..and FAST! Look at these chips, and the surface finish of the machined recess!

Polish

the tool to a sharpness where you are afraid to get your hand near it, and it will reward you!

There was good advice given on

rec.crafts.metalworking, including using milk as a cutting fluid. It works, but using my lathe to make

yogurt caused problems on warm days.

I am fortunate to work at a company that has a big machine shop

(40,000 square feet of mostly CNC's, and probably 20 or 30 lathes,) so I had a good chance to talk to

some of the old hands there. One of the best machinists is an "English as a second language" guy and told

me to "Grinda the HOOK" on the tool, and showed me one he uses for copper.

"Just Use High Speed, Screw

Carbide".

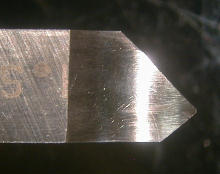

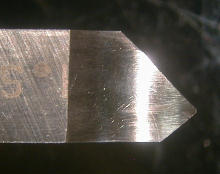

OK. I used a 1/2" tool blank.

I used a Foredom hand grinder to grind the "hook", and

polished it with a Cratex wheel.

Then after grinding the tool to shape, I polished the surfaces on a

#600 diamond lap followed by 4 micron aluminum oxide metallurgical film.

NO OIL was needed!! I just

finished ten pieces in less than an hour on my South Bend Model A, set for a crossfeed of .112 per rev,

at the large headstock spindle with the rear motor drive pulley in the faster position.

UPDATE..Years later.

Don't bother grinding HS tools any more.

If you want a mirror finish with low-power stock removal,

long tool life, and practically no coolant use, get one of these Polycrytalline diamond tools (PCD).

As

long as you don't jam it into the work on an interrupted cut and break it, it will last you for hundreds

and hundreds of pieces.

Here's a nice family-run business that does things right.

For less than

$60, your problems are over.

J&M Diamond Tool

J&M Diamond Tool

Really, if you don't use PCD, you are

playing with yourself

wasting your time.

J&M Diamond Tool

J&M Diamond Tool